Surface Mount Devices (SMD)

https://www.adherasg.com/die-attach-smd-adhesives

Kali terakhir kemas kini

Harga:

R.F.Q

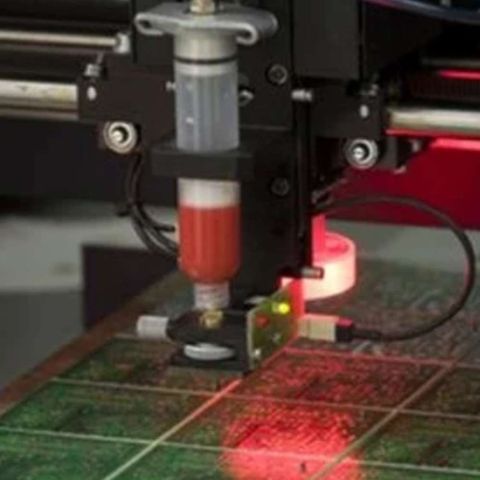

Our advanced surface mount adhesives (SMA) are engineered to meet the demands of high-speed electronics assembly. These adhesives are optimised for a range of application methods, including high-speed dispensing, jetting, and printing. All our SMA products are compatible with Pb-free wave soldering processes and provide exceptional green strength, ensuring components remain securely in place during the critical pick-and-place stage and subsequent thermal cycling. We offer a comprehensive portfolio tailored to specific manufacturing needs, including fast-curing formulations for high-throughput lines and options with varying viscosities to suit different equipment and processes.

Share Product:

Butiran

Key Properties

Formulation: 1- and 2-component adhesives

Applying Methods: Dispensing, jetting, stencil printing

Curing: As fast as 10 seconds at 170°C

Work Life: Work life ranges from 5 to 10 days.

Application-Specific Options:

- Low Exothermic Energy: Minimises heat generated during the curing process, protecting sensitive components from thermal stress.

- Colour: Available in a range of colors, including Yellow, Black, and Red, for process control and compatibility with automated optical inspection (AOI) systems.

- Low-Temperature Curing: Cures at temperatures as low as 80°C, providing a fast cure for high-speed production lines.

- Viscosity: A variety of viscosity and thixotropic index options are available for different application methods.